Old master print etching process used in printing

Some of the commonly used household chemicals for PCB Etching

Some of the possible weak Acids & Chemicals

- ACETIC ACID =

CH3COOH(also written asCH3CO2H or C2H4O2) White Vinegar - CITRIC ACID =

C6H8O7Sour Salt dry powdered form - HYDROCHLORIC ACID / MURIATIC ACID =

HClSwimming Pools to reduce alkalinity - HYDROGEN PEROXIDE =

H2O2First Aid Antiseptic Solution, & Mild Disinfectant for wounds - Sodium chloride =

NaClThe chemical name for Salt - Copper sulfate =

CuSO4

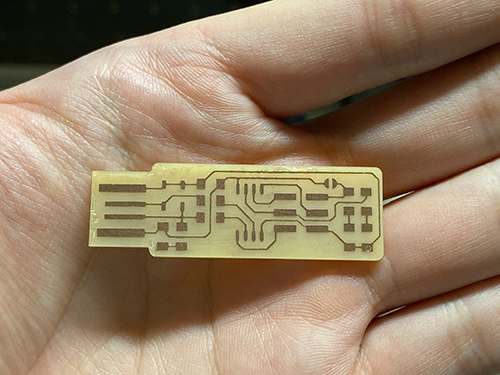

FAB ACADEMY experiments

In 2018 Victor Levy at Fab Lab ULB used laser printing and heat transfer of the mask then Chemical bath and laser cutting for the outline. here

In 2019 Axel Cornu from UlB Lab used Vinyl cut photo-resist layer and Photolithography to create the mask then used chemical bath etching, finally cut the outline with laser here

In Fab Academy 2019 Perttu Piirainen from Fab Lab Oulu used laser scoring and spraying etching machine here

In Fab Academy 2020 Toshiki Tsuchiyama from Fab Lab Kamakura used laser engraving and house hold chemical bath etching steps

Safety First

Don’t get complacent with safety because you are “only using a small amount of a chemical on a small test area!”.

- Proper place: Perform process over a utility sink with running water

- Eye Protection: SAFETY GOGGLES

- Hand protection: Chemical-resistant GLOVES

- Plenty of ventilation: Open a window, the etching mixture might be benign, but it does smell a bit funky while etching.

- Chose the right mixing container: Etching PCBs in metal dishes are not allowed. To do this, use a container made of glass, ceramic or plastic.

- Don’t keep too close: During the etching, the solution will bubble from the copper surface.

Pickling Recipes Comparison

Depending on the availability of components, hams use one of the solutions shown in the table below. Etching solutions are arranged in order of popularity of their use by ham radio at home.

| Name of solution | Structure | amount | Cooking technology | Advantages | disadvantages |

|---|---|---|---|---|---|

| Hydrogen peroxide plus citric acid | Hydrogen Peroxide ( H2O2 ) + Citric Acid ( C6H8O7 ) + Salt ( NaCl ) | 100 ml + 30 g +5 g | Dissolve citric acid and sodium chloride in a 3% hydrogen peroxide solution | Component availability, high etching rate, safety | Not stored |

| Hydrogen peroxide plus hydrochloric acid | Hydrogen Peroxide ( H2O2 ) + Hydrochloric acid ( HCl ) | 200 ml + 200 ml | Pour 10% hydrochloric acid into a 3% hydrogen peroxide solution. | High etching rate, reuse | High accuracy required |

| Aqueous solution of ferric chloride | Water ( H2O ) + Ferric Chloride ( FeCl3 ) | 300 ml + 100 g | Dissolve ferric chloride in warm water | Sufficient etching rate, reuse | Low availability of ferric chloride |

| Aqueous solution of copper sulfate | Water ( H2O ) + Copper sulfate ( CuSO4 ) + Salt (NaCl) | 500 ml + 50 g + 100 g | Dissolve table salt in hot water (50-80 ° С) and then copper sulfate | Component Availability | Poison of copper sulfate and slow etching, up to 4 hours |

Other Recipes

CITRIC ACID and HYDROGEN PEROXIDE

For each cm² (square centimeter) of 1-oz copper PCB to etch, mix:

- CITRIC ACID, anhydrous or otherwise 0.15 grams

- HYDROGEN PEROXIDE 4 mL

- table salt, NaCl of any kind 0.05 grams

HYDROCHLORIC ACID and HYDROGEN PEROXIDE

- HYDROCHLORIC ACID 30% is sold at the hardware store as MURIATIC ACID 30% or 10 molar (37% 12 molar is fine too) used for pool cleaning

- HYDROGEN PEROXIDE 3% for cleaning cuts available everywhere

- STEEL WOOL or RUSTY NAILS (not shiny galvanized ones)

ACETIC ACID & HYDROGEN PEROXIDE

- White vinegar no less than 4% ACETIC ACID.

- Hydrogen peroxide is the standard 3% strength that you can buy in any drug store. Check the first-aid section.

- Salt (NaCL)

Start to finish, etching takes 20 minutes for small boards, or up to an hour for large ones.

mix one part vinegar with one part hydrogen peroxide.

You need enough solution to cover the board with about 1/2″ of liquid.

Add a couple good shakes (maybe 1 tsp?) of salt and stir it all up with a gloved finger.

- Drop your board in the solution, copper side up. It should make some very fine bubbles. If you don’t see tiny fizzy bubbles, add a little more salt.

- Within about 30 seconds, you should see the copper areas collect a yellowish brown layer of gunk.

- Every 60 seconds, wipe the board off with a foam brush. Do not remove the board from the solution. Just stick the brush in there and wipe the brown gunk off. Wiping the gunk off every minute dramatically speeds up etching.

- Every ten minutes or so, pull the board out (wearing latex gloves) and check on it. When it’s nearly finished, you’ll see patches of fiberglass PCB no copper on them.

- As the board gets close to done, start checking it more often. The solution will turn darker and darker blue, which makes it hard to see. You want to etch the board until the excess copper has been removed, but not any longer. Etching for too long will start to damage the traces and pads. The photo-resist chemical can protect the copper for a long time, but eventually the etchant will get under it. If you’re using fine traces (0.01″), you need to be more vigilant about not over-etching.

- Every so often, you can add a little salt, which seems to speed things along a bit. Add salt if you don’t see any tiny fizzy bubbles.

- When etching is complete, rinse the board off with water Using a cotton ball, wipe the board with nail polish remover (acetone).

http://www.seandawson.xyz/the-best-pcb-etchant-from-household-materials/

http://quinndunki.com/blondihacks/?p=835

https://hackaday.io/project/19898-make-your-own-pcb-etchant

Chemistry

Dilution of a solution

c1 x v1 = c2 x v2

c = concentration

v = volume

Example:

Dilute 10 ml of 6% H2O2 to 3% H2O2

c1 x v1 = c2 x v2

6(%) x 10 = 3(%) x ?

? = (6 x 10 / 3 ) = 20 ml

20ml - 10 ml = 10 ml (Add 10 ml distilled water)

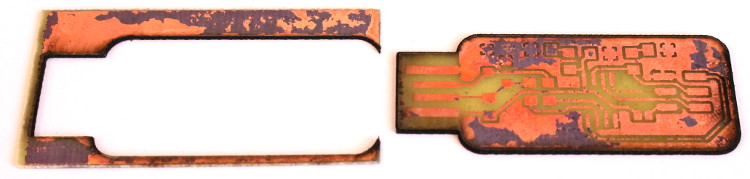

A copper board is made of an epoxy resin board covered with a thin layer of copper. The etchant reacts with the layer of copper and dissolves it, except where a mask protects the copper. The epoxy is left intact as it does not interact.

Here are the two chemical reactions taking place :

Ferric chloride’s (aka Iron (III) chloride)

FeCl3 + Cu --> FeCl2 + CuClVinegar/hydrogen peroxide/salt mixture’s.

H2O2 + 2(CH3COOH) + Cu --> 2(CH3COO-) + Cu2+ + 2(H20)

The reactant is the result of the combination of acetic acid (which represents 80 grams per liter of white vinegar according to the bottle [which says 8° acidity]) and hydrogen peroxide (which is at 3% mass concentration).

We can calculate the optimal ratio of each component in order to get a maximum amount of it.

Hydrogen peroxide is 34 grams per mole and acetic acid is 60 grams per mole.

So, in a liter of vinegar there are 80 grams of acetic acid which represents 80/60 or 4/3 moles of acetic acid. In a liter of hydrogen peroxide, which approximately weighs a kilogram, we have 3% x 1000 grams = 30 grams, nearly a mole, of pure hydrogen peroxide.

Because the reaction uses twice the number of hydrogen peroxide molecules of acetic acid molecules we can say that we need to put roughly a 2/3 ratio of hydrogen peroxide/vinegar in volume to get things optimal.

Now you may be asking yourself “Why do we want to add salt to that ?”.

Well, one possible explanation (I'm not actually sure it is the right one) is that the reaction brings neutral Cu atoms of the board to Cu2+ ions in solution that would form copper acetate (it is the combination of one Cu2+ ion and two CH3COO- "acetate" ions). And, at one point the bath would reach an equilibrium (because there is as much Cu2+ forming from Cu than Cu2+ getting back at a solid Cu form).

Generally this happens before your board gets its beautiful tracks, which is quite sad. Table salt, or NaCl, brings chloride ions Cl- to which Cu2+ ions will bond to form cupric chloride or CuCl2 instead of being left in solution (those ions would endlessly come back and forth from Cu to Cu2+). You can see this during the reaction (if you leave the reaction with no salt it will turn blue which is the color of copper acetate and stop, whereas if you put salt it will turn green, the color of cupric chloride, and carry on).

2Cl- + Cu2+ --> CuCl2

By doing so, the equilibrium point is pushed forward and more copper can be dissolved, so that, if you are generous on salt (if you introduce table salt in excess) you may get your PCB in the end ! One tablespoon of salt on the board is generally sufficient.

Hypothesis : Given the concentrations of hydrogen peroxide and acetic acid in our "recipe" ferric chloride should be way more efficient. However the Salt/Vinegar/Hydrogen peroxide seems to be both less expensive and safer.

Chemistry 2

Hydrogen peroxide is what we call an oxidizing agent (a mild one), meaning that it easily accepts electrons from other species to form H2O (hydrogen peroxide itself is electron deficient). What happens when it “dissolves” copper metal is that a neutral copper metal atom releases two electrons, to form a Cu2+ ion in solution. All metals tend to release electrons to form positively charged species….we refer to anything that DONATES electrons as a reducing agents. The strength of metals as reducing agents varies and copper is a fairly weak reducing agent. I did a demonstration in my general chemistry class recently where I dissolved a piece of copper metal in concentrated nitric acid….again copper loses electrons to form Cu2+ and H+ ions from the acid gain electrons to produce hydrogen gas. If you see a bluish color to your solution after the copper is dissolved, it is due to the presence of the Cu2+ ions.

The other components HC2H3O2 is acetic acid, and yes it gives the characteristic taste and smell to vinegar. It is a relatively weak acid, but aids the oxidation-reduction reaction between the copper and the hydrogen peroxide by providing a source of H+ ions to solution that are used to form two H2O molecules from one H2O2.

Chemistry 3

Hydrogen Peroxide oxidizes the copper, and by supplying the required proton the acetic acid goes on to form copper acetate. The salt appears to be a catalyst, where it forms an intermediate dark green/black copper chloride on the surface, which is then converted to copper acetate with mixing. Perhaps it helps stabilize newly formed copper ions. I can’t quite tell, but certainly a much smaller than stoichiometric amount is only needed to speed up the reaction.

NOT VERIFIIED INFORMATION

This is a harmless side reaction where the peroxide is decomposing to water and oxygen gas. Obviously don’t keep too close as the effervescence will sputter the etching solution up, which at this point will be acidic, oxidizing, and contain some amount of copper chlorides.

Since H2O2 is a mild oxidizing agent (and can sometimes be a reducing agent if combined with a very strong oxidizing agent), it should only be dangerous to other weak or strong reducing agents. It may do this much more slowly depending on the metal. I wouldn’t leave it in contact with aluminum, nickel, or other common metals for long periods of time.

https://www.instructables.com/id/Is-the-best-PCB-etchant-in-every-kitchen-/ http://www.stephenhobley.com/blog/2011/03/02/still-messing-with-forces-i-dont-understand-the-formula/

Other

http://nasweb2.dscloud.me/wordpress/2017/11/19/etch-own-pcb/?print=print

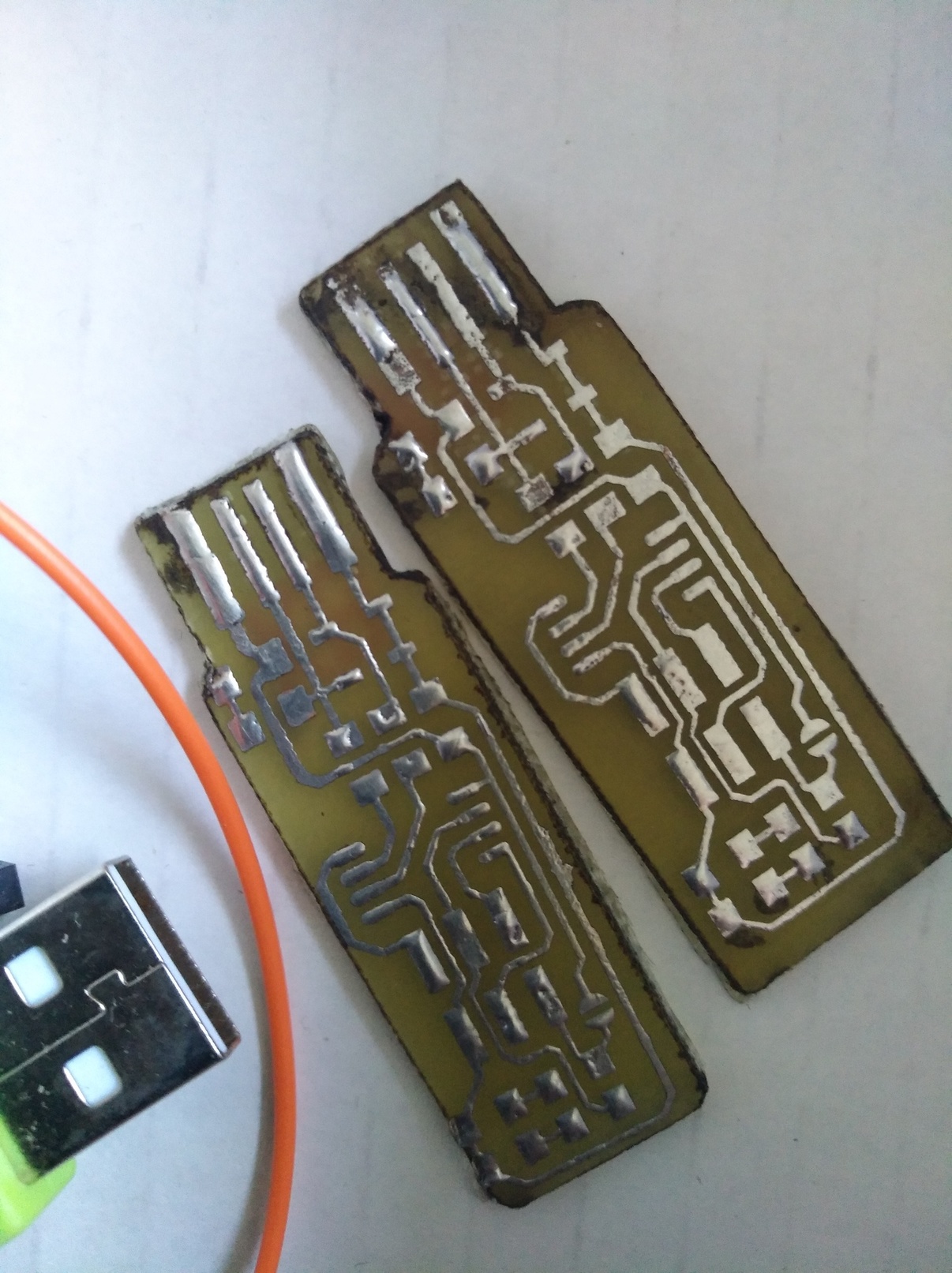

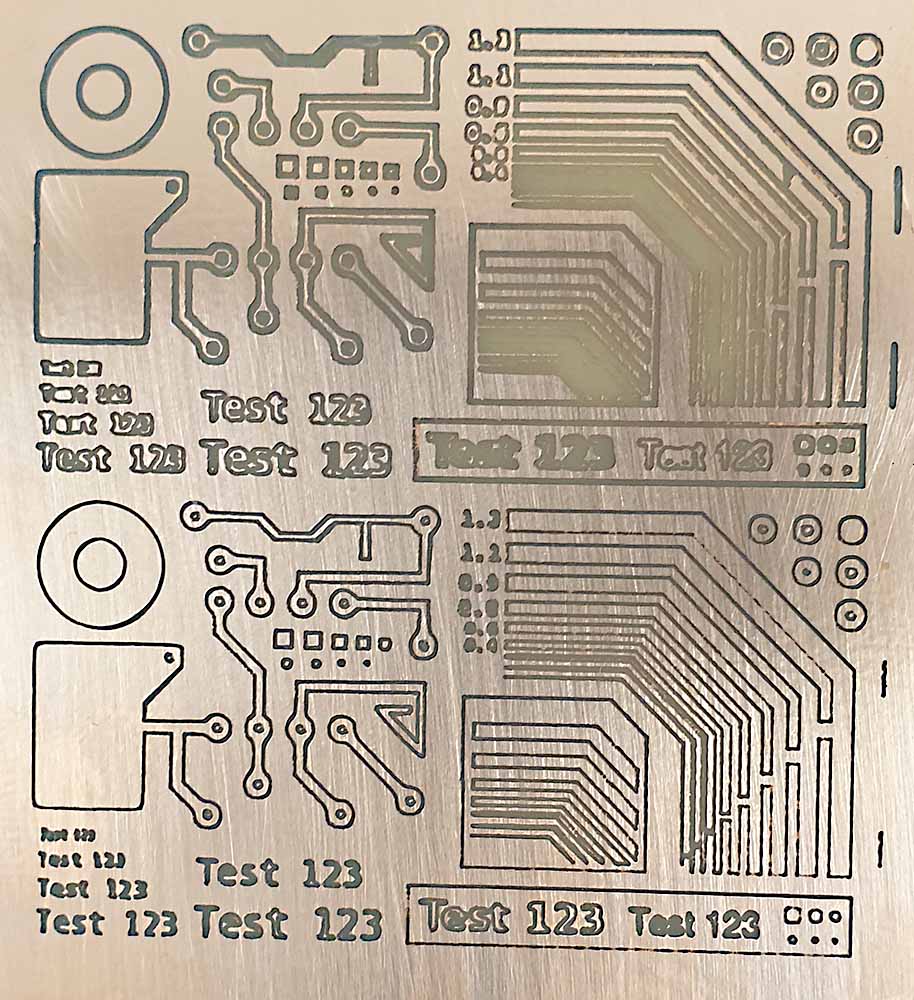

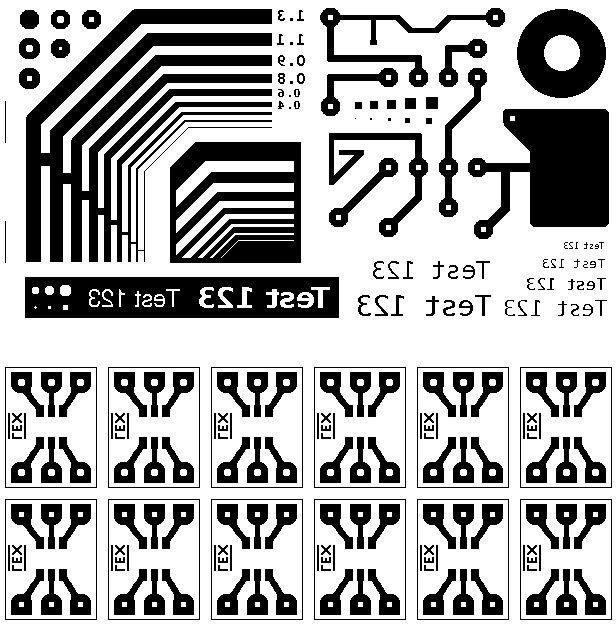

Etching Quality Test

You can Design your own on a Circuit Design Software (Eagle)

test4

test4

http://nasweb2.dscloud.me/wordpress/2017/11/19/etch-own-pcb/?print=print http://www.seandawson.xyz/the-best-pcb-etchant-from-household-materials/

Laser Photo Transfer

https://www.instructables.com/id/Is-the-best-PCB-etchant-in-every-kitchen-/

https://hackaday.com/2012/02/15/etching-pcbs-with-vinegar/

http://dimitarangelov.com/make-pcbs-at-home/#page-content

Waste management

Once all the unmasked copper has been etched away, take out and rinse off the board with running water. The remaining blue solution will contain dissolved copper salts which are not environmentally friendly and very toxic to plant and aquatic life.

Reusing etching solution

Reusing the etching solution is not favored because it results in slower and more messier process. Using fresh mix every time is preferable.

Disposing of the etchant.

Dispose of the spent pickling solution into the sewer?! There are a lot of opinions on this, and people are very, shall we say, passionate about it. In my opinion, you can either throw it in the trash or pour it down the drain. Putting it in a container and dumping it in the trash also seems fine.

Neutralizing the acid & precipitating the Copper

Adding sodium bicarbonate (baking soda) in small amounts at a time; the solution will fizz and release carbon dioxide gas.

This will neutralize the citric acid, and precipitate out the copper in the form of copper carbonates.

The solution is sufficiently neutralized when no more fizzing occurs on bicarbonate addition.

At this point the liquid can be safely disposed of (down the drain in small amounts), and the left over precipitant can be disposed of as solid waste (in the garbage.)